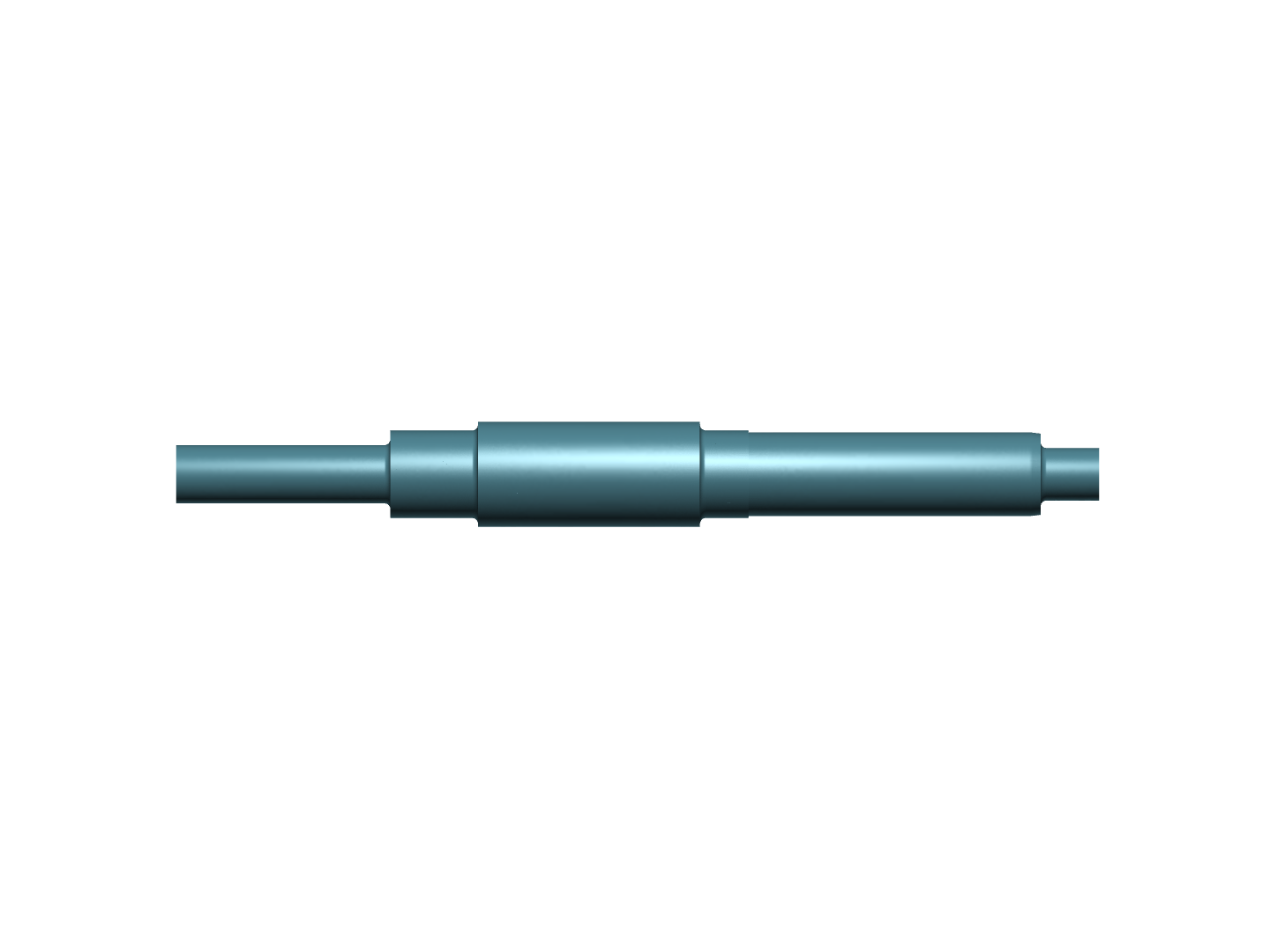

Centrifugal Pump Shaft

About this project

2 cases of a centrifugal pump shaft are studied. In the first case fatique of the shaft is studied. The maximum bending stress in the shaft will be determined, caused by impeller imbalance, impeller weight and radial load of the engine. The bending stress must stay below the materials allowable bending stress for fatique of 74 N/mm2. Also the maximum bending of the shaft is important here, which is only allowed to be 50 micrometer at the stuffing box by ISO 9908. The plane of the stuffing box is located at 399 mm from the coupled side of the shaft. For the second case the mechanical strenght of the shaft while undergoing the engines pull-out torque (maximum torque of the engine). This is required to asses the shafts minimal diamater (on which the impeller is attached), so that no plastic deformation will occur. To prevent plastic deformation the maximum stress in this part of the shaft must stay below the materials yield stress of 220 N/mm2.

Related Projects

by simscalesimscale

by Ali_ArafatAli_Arafat

Project History

vorsid created this project